Thunderbirds

http://islandsportsrepair.com/portal/concept-to-complete/9-airbrushing#sigFreeId2ddaa157b7

Airbrushing starts at $400.

(Typically 3 colors + black & white, team logo, or jersey number)

Get a custom airbrush design on your helmet.

Express your individuality or proudly display your team logo and colors.

Ready to discuss a design? Send me an email at:

This email address is being protected from spambots. You need JavaScript enabled to view it.

to schedule a time to talk.

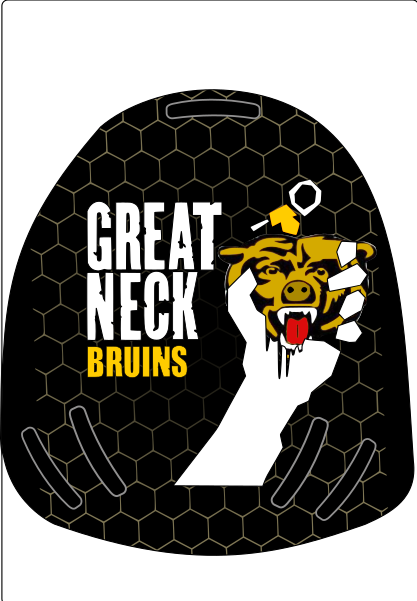

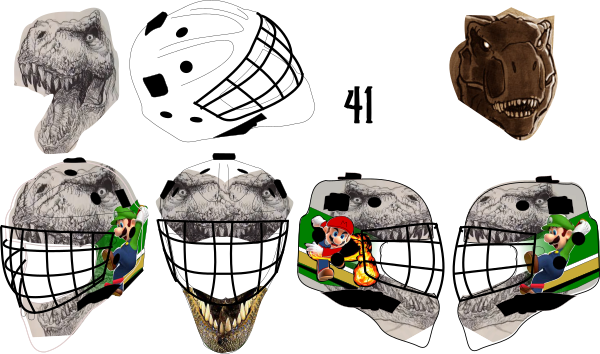

We use computer graphics so you can visualize the final product in Concept - Complete.

Cost increases based on:

- Complexity of the design (the more components, the higher the cost)

- Amount of colors

- Using special paints and glittery application

- Portraits

- Repair to old helmets. We will not paint over cracks or chips.

- Backplate design

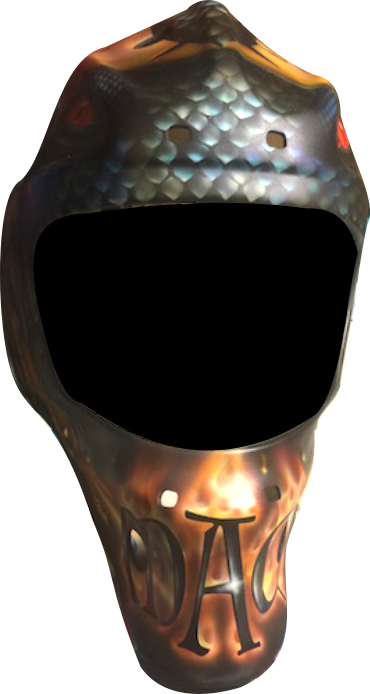

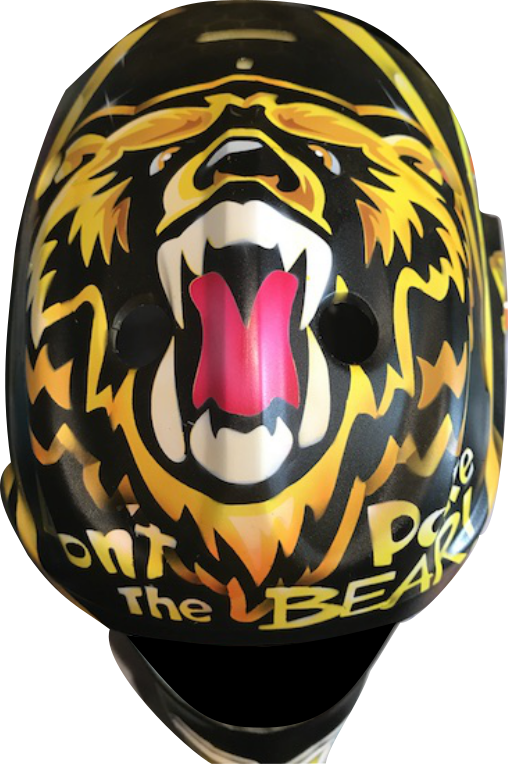

All helmets are finished with automotive clear coat for a durable finish.

We will require a $50 deposit during the design process. This will be applied to the final cost of the artwork. We reserve the right to limit the amount of changes to the design. Once approved and the painting process has started, we cannot allow further changes.

Important:

We can paint helmets made of Lexan Polycarbonate helmets but they may not be as durable as helmets made of a composite material, such as kevlar or fiberglass. Youth and junior helmets are typically made of Polycarbonate material.

New helmets are preferred. Helmets that have prior paint or chips require additional preparation and will add to the final cost.

Your Goalie Helmet Airbrushing Headquarters!

Have your Goalie Helmets airbrushed to your specification

Simple to complex, we work with your budget.

We are in Long Island, New York.

Let's discuss airbrushing your goalie helmet!

Call or text

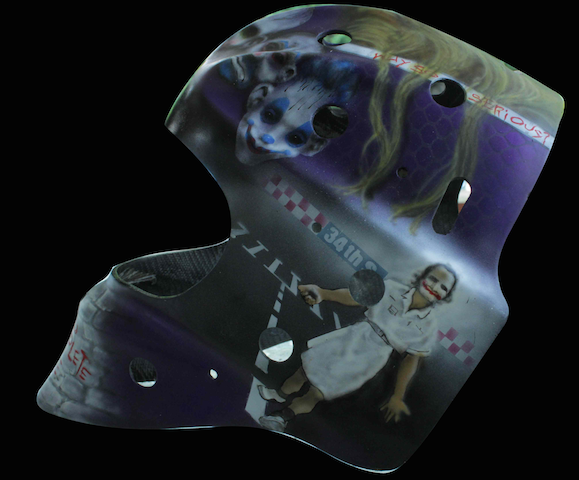

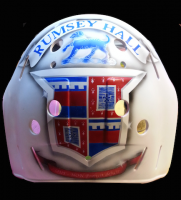

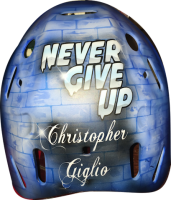

Current Project

2019

2018

2017

2016

Older

Backplates

Goalie equipment is, bar none, really cool.

There is no other sport or position that comes close.

Stand out from the crowd with custom paint on your lid.

I studied Illustration and Design at the Fashion Institute of Technology in NY.

Airbrushing a helmet is a time intensive process.

There is a lot of preparation before and after the actual painting.

These links can help you understand the how I price my work and some insight into the entire process

Airbrush Info

The Airbrush Process

Step-by-Step Photos

Customer Gallery

Concept to Complete

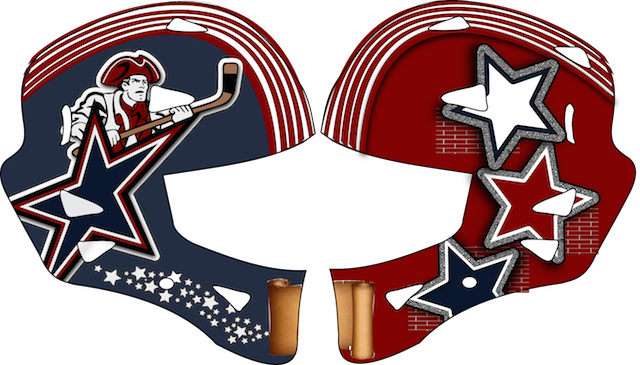

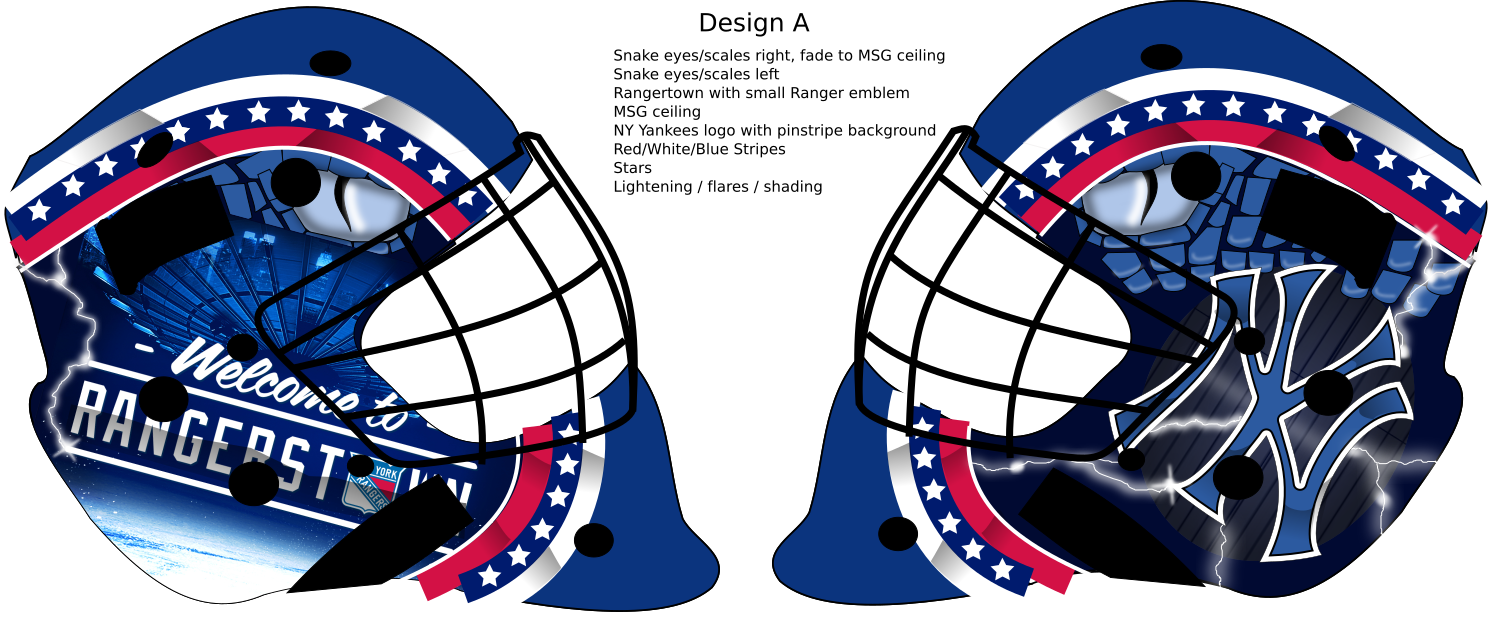

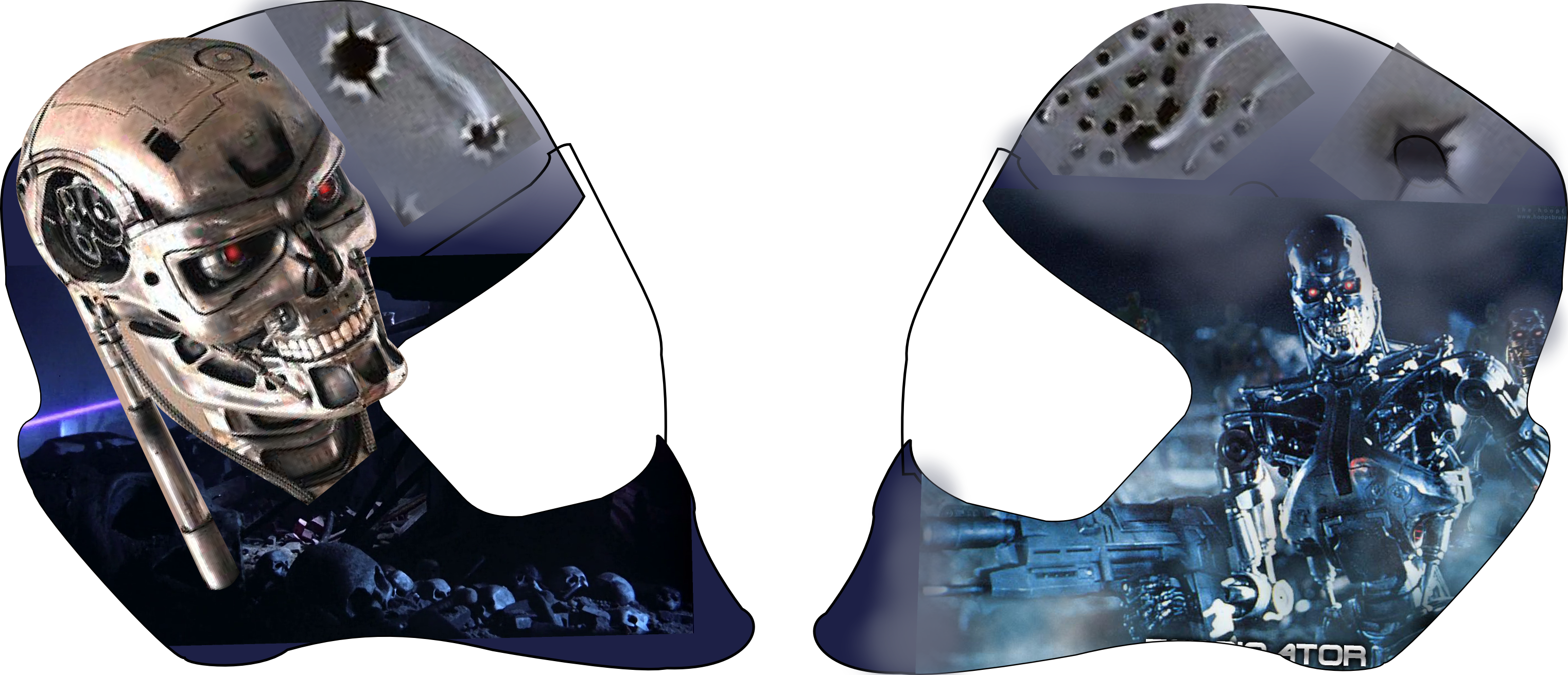

We conceptualize the design using computer graphics for your approval.

The design is followed closely during the painting progress.

Minor adjustments may occur due to the curves and hole features of the helmet

and to create balance of the graphics.

My process starts with creating a computer generated design of the graphics that will be applied to the helmet. (See Concept to Complete) This art work will also be used for the design and approval process and also to cut out masking material that will be used in the airbrush process. Several masks may be cut for each design depending on how many colors and the complexity.

Depending on the design, I may add lightening, lens flares or other items that connect the graphics together.

As part of my process, I apply a background pattern that is usually visible up close. It can be a hint of a brick wall, stripes, dots stars, or something more elaborate. If you look at my past helmets and zoom in close, you will see some of these patterns. It will make the main graphics appear more dimensional when complete.

Once approved and I have the helmet, I start removing all hardware. We prefer to work on new helmets.

If you have a helmet you have been using, the condition will be assessed. Chips and cracks can be repaired at additional cost. (See our Helmet Resin Repair page) On helmets that are not new, we may have to cut out rusted hardware which will be replaced with new hardware at no extra cost. If you need/want to replace the cage, you can do so at an additional cost.

Depending on the manufacturer, I either remove the padding or cover it so it does not get overspray paint.

The helmet is then sanded in all curves and crevices so that the paint will adhere, then cleaned to remove any oils or waxes.

A coat of primer/sealer is applied. The graphics are printed and taped to the helmet for sizing and determine interference of straps and holes.

When the airbrushing is complete, a few coats of automotive clear coat is applied to protect the paint. When it is fully cured, the hardware (and padding if applicable) is reinstalled and is now ready for delivery.

Backplates require all the prep work as stated above. The stickers will be removed. If I can remove them in one piece I will stick them to the inside of the backplate (sometimes they just fall apart). The glue must be cleaned off before sanding and priming. Artwork is created and masking material is cut for the design and a final automotive clear coat is applied. The cost of backplate is $50 for a one color to match the helmet (only if the helmet is also being painted). A simple design (number or name) would be $100, more if the design becomes more detailed.

A new backplate harness can be created in the color of your choice. The harness that allows greater exposure of the surface is stitched in and is a separate cost.

As you can see, it is labor intensive. The airbrushing is only a part of the entire process.